HANDS ACROSS THE WATER

A JOURNAL

HANDS ACROSS THE WATER

A JOURNAL

The timing is perfect. Once again we are all up to midnight grinding and working in the powder glass.

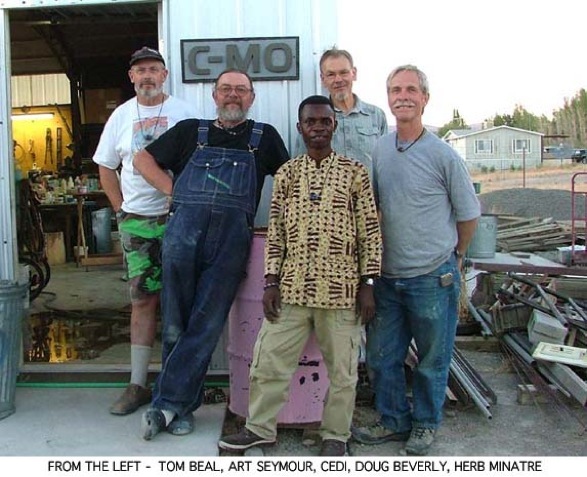

All this work going on at so many places in the shop with so many people has the place in a frenetic state of chaos. I believe we have used every tool in my inventory and that is something. Tools and parts have coalesced in the hot shop from every building on the place and everything is out of place. Still work is getting done at a pace. Cedi, at one point after spending some quality time in conversation on the ramp with Tom and Herb talking about the crusher and the grinder comes up to me with a grin and says that now he is an engineer! Herb and Tom are in fact mechanical engineers and the knowledge they impart to Cedi is for him like spending time with wizards. Cedi tells me that in Ghana engineers know books but not machines on the ground and now after spending time with Tom and Herb he is more well educated in field engineering than the Ghana engineers. This is an unexpected and positive outcome for the workshop indeed.

Sunday afternoon, I Pick up Herb at the airport. We come home, do a major walkabout around the shop, and then sit for a viewing of the Cedi video from Karrie Stewart with a burrito for supper. We then adjourn to the shop for an evening working at powder glass chevron on the stick. We both get a credible effort cooking in the oven and retire to bed - fairly late.

Monday we are up and at it by six and I get the shop set for a glass charge. All the colors and the white batch are brought into the shop and laid out in their respective positions. By ten all the furnaces are ready and the charge is going in. This is my first effort with raw batch in the big blue electric melter and it presents some issues which we work out. The glass melts fine. We spend the day in the shop preparing the work areas and melting and cleaning up after the melt. At three o’clock we head into Reno to pick up Tom at the airport. We swing by Atomic Stone on the way in to check out Doug’s remodel, and make it to the airport just as Tom arrives. A quick stop at Costco after we pick up Tom and we head on to home. There we get Tom ensconced in his bedroom and give him a walkabout. We have dinner and watch the second half of the Cedi video then repair to the shop for a session with the powder glass. Tom is a natural and puts a great effort together right away only to lose it just before getting it into the mold. He starts another right up and makes a beaut. I get a fair bead made and continue shop work preparing the workspace for the workshop while the guys get to know each other and work with the powder. We go until midnight and turn in so as to get a little rest before Tuesday and picking up Cedi.

Tuesday morning Tom is up and at it and makes us a big breakfast while Herb and I are working in the shop. I’ve got a microwave out there and have burritos in the shop fridge for lunches and also have pizza slices frozen with a dedicated oven for cooking them. Everyone gets after their powder beads to grind them before Cedi arrives. We leave at noon to make sure to be at the airport early. Both the guys have cameras and Herb has my movie camera. Cedi’s plane is twenty minutes late and when he arrives I greet him with camera’s clicking and Herb finds that the Movie camera has unexpectedly quit operating. What a deal. Onward to the baggage claim and we get Cedi’s luggage and are off to the car. Our path home takes us up into the mountains and around the east shore of Lake Tahoe which Cedi finds fascinating. Neither he nor Tom have ever seen it. We make it down into Carson City by around three thirty and, having found out some of Cedi’s food preferences, stop for some groceries. Cedi enjoys the supermarket experience. He insisted on pushing the cart. While at the store I call Melissa and arrange to borrow their movie camera, and we stop and pick it up on the way home. Then we head directly to Stagecoach where we unload and get Cedi set up in his trailer with the air conditioning. He is very animated and is eager to see the shop so we head out and find ourselves working in the powder glass within the hour. He soon remarks “ I am at the right place” He repeats this remark several times over the next few days. I show Cedi the glass crusher and demonstrate it and then we run a big batch of red glass through it. Cedi gets real excited about the crusher and also the red glass. It’s a red he can really use. So we agree that the crusher is definitely headed to Ghana. This machine was a gift to the project from Joe Rice in Indiana. Tom and Herb have already talked about the machine and have set a plan to rebuild it and also to dismantle it and rework it so it can travel and reassemble easily. Tom’s job for the next two days will be working on the crusher.

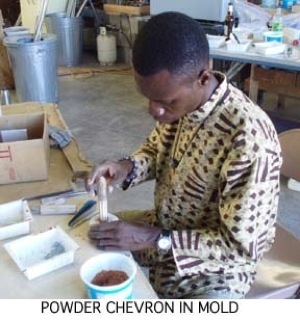

I then demonstrate to Cedi one of my powder glass chevrons and he sets about trying the technique. After three failures he stops and begins to think about a less clumsy approach to the problem. We all talk about it while Tom and Herb make us some supper. Herb is our salad master and Tom the entre’ chef. In the evening Cedi has a plan and we go out to check it out. He decides to make the chevrons inside out from the outside in. He makes the powder damp and packs it around the inside of the mold and tools it there. The technique shows promise. We keep at it til near midnight when I call an end to the day as a six o’clock start up is agreed upon to beat the heat with the hot work in the shop. We haven’t even had day one yet and are already checking off things on our list of items to do.

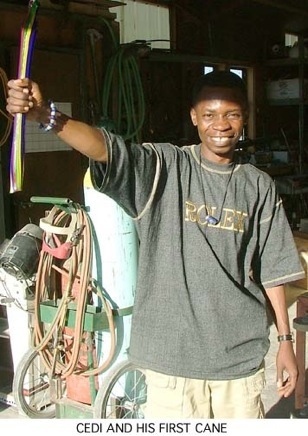

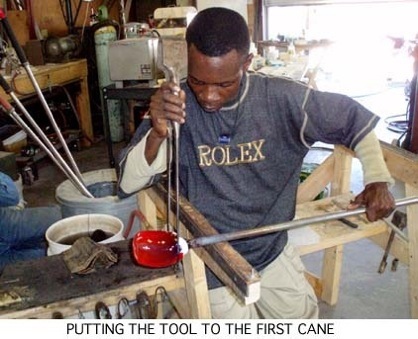

Wednesday I pull several canes while Cedi watches and we discuss what I’m doing, then I get him to help me make a cane which unbeknownst to him is a CD signature cane for him.

THE CEDI CHEVRON BEAD MAKING WORKSHOP - STAGECOACH, NV - JULY 07

CEDI

When it’s done and in the oven I show him the end of the pipe where he looks quizzickly at it, and reads it and says C......D...... CD!!! He’s astounded and pleased. We get the whole thing on film. This was scheduled for Thursday so We are still one day ahead. It’s early afternoon by now and after shutting the glory hole down and getting the glass charge set up go in for lunch. I’ve been getting calls all this while about the new backup generator from the generator company in Reno. Ernie their office girl says it’s done and we need to come and get it because it’s in their way. Herb is ready to head in when I call back to find out if for sure they have done all the work on it and sure enough it’s not really done, so we set ourselves up for Herb to pick it up on Thursday morning. We spend the rest of the day and night doing the glass charge and working on powder beads. Doug Beverly brings us dinner and stays on into the evening to work with the powder glass and to get to know everyone.

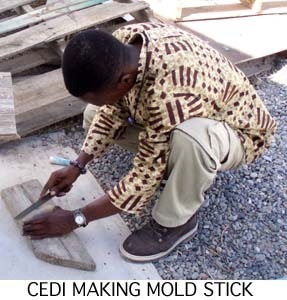

Cedi demonstrates his powder technique and also having seen the huge bucket of dead cane outside and declaring that he can make it work for beads sets about cooking up several pieces of the cane and shaping them in my clay molds. He says the molds aren’t shaped right and asks for a file and a stick and begins to make a tool to form a mold correctly with the clay I have on hand.

He gets right at it makes three molds directly. The clay is thick and in a proper world would need near two weeks to dry before firing , but Cedi is master of his technique and over the next two days eases the molds into dryness by carefully moving them about the shop throughout the day, and near the furnaces and such. By Friday morning they are dry enough to go into the annealer in the morning and get up to 925. Later in the afternoon I fire them up to 1650 which is a serviceable firing for them to be used.

Thursday morning finds us all up early and getting ready. I rise at five and get the glory hole lit , oven on and the punty warmer going. I made three vases first thing on Wednesday to lower the pot levels and I hold a lottery and give them to the three guys. Good stuff that. On to chevron cane and Herb and Tom head into Reno for the generator while Cedi and I stay in the shop with the glass. The first cane has a hole too big and the next one starts out with a lopsided gather so I decide to decorate it on the spur of the moment. I get Cedi to come sit with it while I add stripes all over the outside onto the white ribbed layer. The thing goes together pretty nicely and I decide to pull it hot and twist it up. Bang! It’s too hot and is all over the place. Cedi and I are chasing it all over the room and after a hefty dance and frantic recovery I load a mass of tiny striped cane parts into the oven. some bent , but hole through it all.

Some of the cane is smaller than 1/8 inch diameter. After the frantic moment getting the cane into the oven, I take a small piece that doesn’t make the oven and grind it into a bead. Cedi is watching all this intently. He then compares this tiny bead to an old one in Ghana which is highly prized. At this point we are pretty wired up and it’s noon and the boys come home with the big generator in tow and hamburgers and fries for lunch. After eating in Bills cool trailer Cedi and I are back at it in the shop where I make two more pulls similar to the others and keep the heat better. I twist the first and Cedi asks if I will do it again and make it Chevron......... Herb and Tom and I figure that proper chevron in Ghana must be straight grained so I pull another and keep it straight. By now it’s time to finish up with hot work and begin the charge so off goes the glory hole and right away, while I’m getting the glass together, Cedi is working with the powder. He decides on another approach to the powder chevron and wants to carve a ribbed mold of wood. I catch him at this after a bit and dig out the ones I’d made for making ribbed clay molds. Voila! He says they are just what the doctor ordered. He then proceeds to make a real nice shot at a powder chevron in the mold inside out. He says that watching the cane process gave him the idea for the mold approach.

In the end he has trouble with the firing and says that my powder is not sized right he will do it at home with his powder which is more well suited for the technique. Onward and upward, he moves on to cooking the compromised cane chunks to good effect in my clay molds.

While all this is going on, everyone is cycling through various grinding steps on their various beads and on chunks of cane I provided from the previous day’s pulling.

It’s a busy time. About now I suggest to Herb and Tom that they build a crude motor mounted on a board to demonstrate to Cedi how easy it will be for him to get a grinder going with the diamond wheels I have for him to take home. They step right up and by Friday afternoon it’s built and up and running just as Cedi is asking for a coarser grinder for all this grinding. He doesn’t have any machines at home, but is taking to the grinding well. He sees how it’s necessary for the chevron.

click here to continue workshop journal

Friday morning I spend two hours on the phone calling ahead to the airlines for excess baggage information and then calling all over creation for welding supplies and grinder rebuilding parts. I don’t get on to the pipe until ten and Herb heads off to Fallon for welding rod, lumber, machine tools etc. for building the crusher parts and also building the shipping crate. He comes back around noon with all the goods after Cedi and I have been making cane for two hours.

I had no plans at the beginning of this workshop to put Cedi on the pipe as I didn’t know how well we would be able to communicate, especially in the clinches of hot glass work and I didn’t have a clue as to his hot glass acumen. After having him assist me for two sessions I could see that he was very alert, observant and had a deep understanding of the properties of hot glass despite having only had one brief glass blowing workshop some five years back in Holland. Hot glass is hot glass and Cedi has thirty plus years experience with warm and hot glass in molds and manipulating it there. I decided to leap ahead and jump in with both feet.

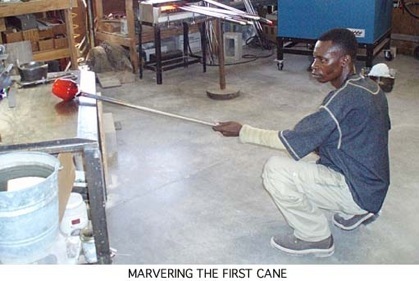

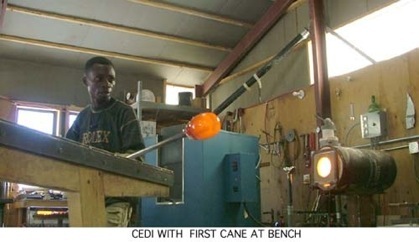

After lunch I go out, make a cane and then put Cedi on the pipe and walk him through his first chevron cane. I didn’t give him any forewarning as I wanted to see how he handled it. He was ready. He was more than ready. I did the gathering for him as there are three furnace types each with its own door geometry and I felt it unfair to subject him to that kind of chaos at the beginning of his journey. He handled the hot glass well and took direction well. He made a bubble with modest effort and developed it well.

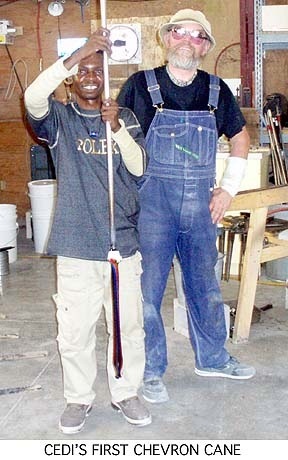

We got it all on film and had a joyous celebration of the moment. Thursday I had red, yellow, green, and purple in the pots. Cedi suggested blue so we would have the Ghana flag colors all at once. I changed out the purple for blue and his cane made on Friday has the Ghana flag colors. We made it with the same decoration as I’d been doing for two days and continued with through Saturday.

After that he did all the molding and shaping at my direction. He followed my directions with the heat well and we got a credible pull. I kept it on the small side to ease him into the process.

it’s a pretty successful cane save that later we found that it got put away a little cold and some of it cracked. We were all so joyful over his success we didn’t get it into the oven quickly enough. He made another cane after that and we got the heat right to make the beads bigger as he wanted to, and though again we put it away a little cold it was a smashing success.